43 diagram of blast furnace with labels

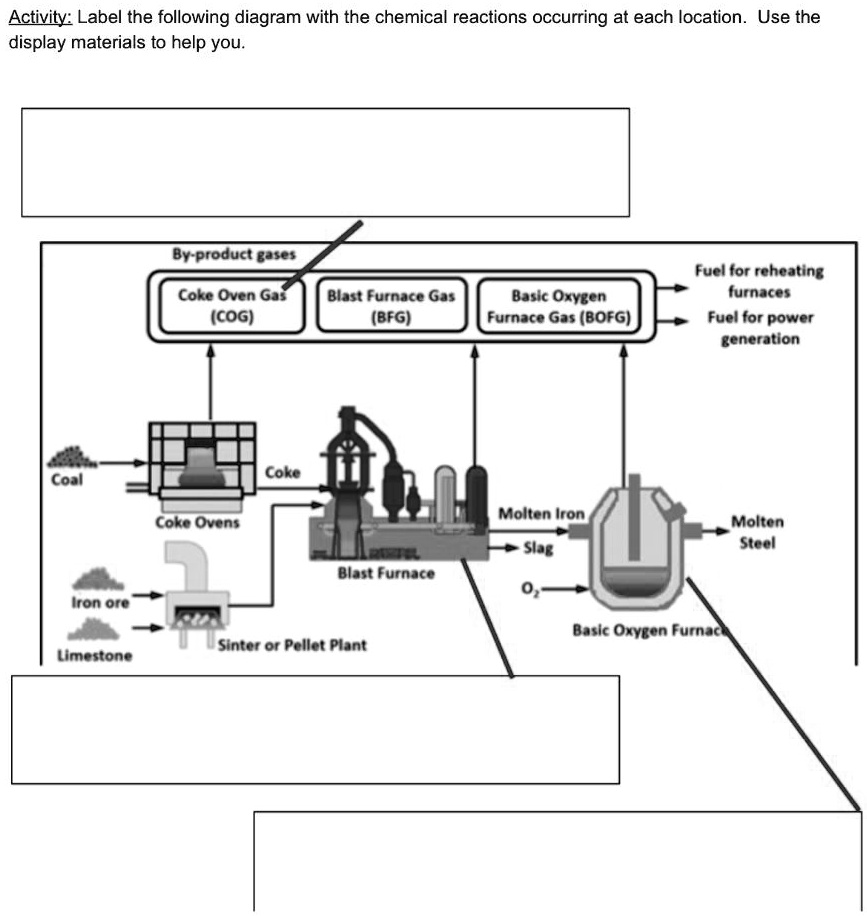

ruud ugph furnace furnace wiring diagram Diagram Of Blast Furnace With Labels In 2020 | Blast Furnace, Furnace . csma slag. Ruud Silhouette Furnace Wiring Diagram - Complete Wiring Schemas wiring89.blogspot.com. ... Wiring diagram rheem furnace pump heat gas honeywell heater schematic visionpro fan ruud 125a water motor regard switch turns mounting. Ruud furnace. Blast Furnace: Introduction, Definition, Construction, Working ... A blast furnace is a special type of cylindrical furnace, which is basically used for the purpose of smelting. So, the industrial metals can be extracted from their ores like iron, pig iron, or copper. The word 'blast' gives the idea of combustion air which is forcefully supplied or produced to the atmospheric pressure above.

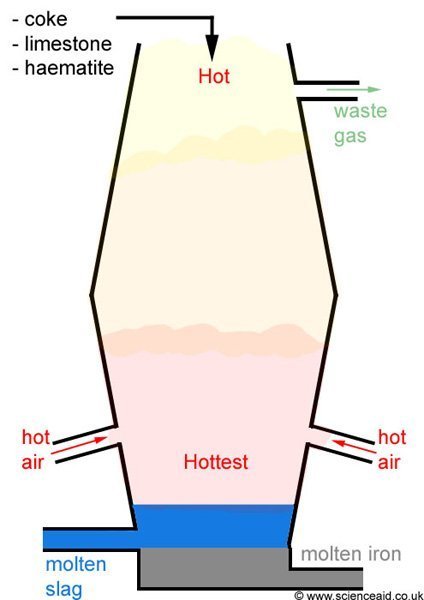

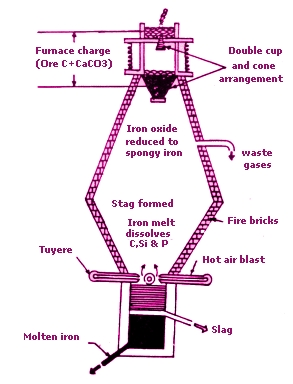

Draw the diagram of the blast furnace used in the extraction ... - Vedantu Extraction of Iron Answer Draw the diagram of the blast furnace used in the extraction of iron and label the molten iron. Answer Verified 213.3k + views Hint: We have to draw the diagram of the blast furnace used in the extraction of iron. It is used for the common ores like iron oxides to extract the iron with the help of reduction with carbon.

Diagram of blast furnace with labels

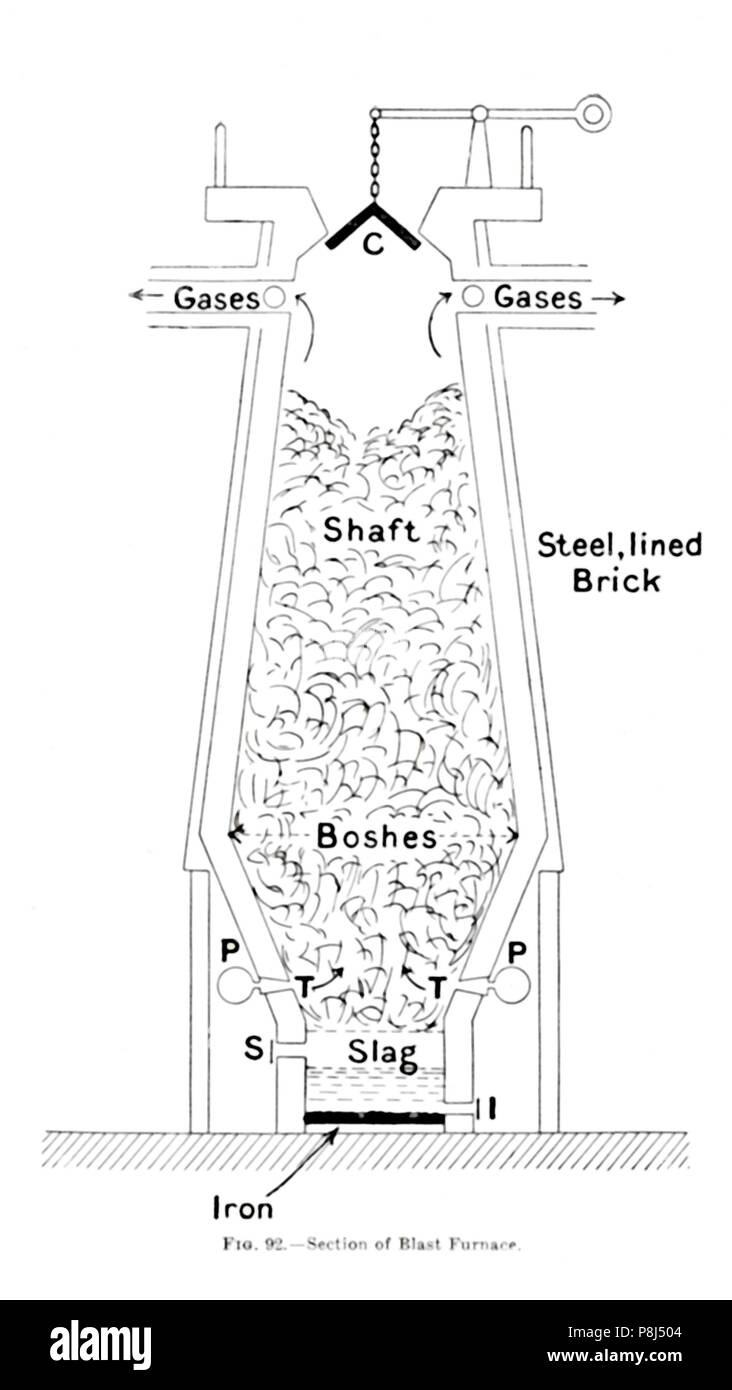

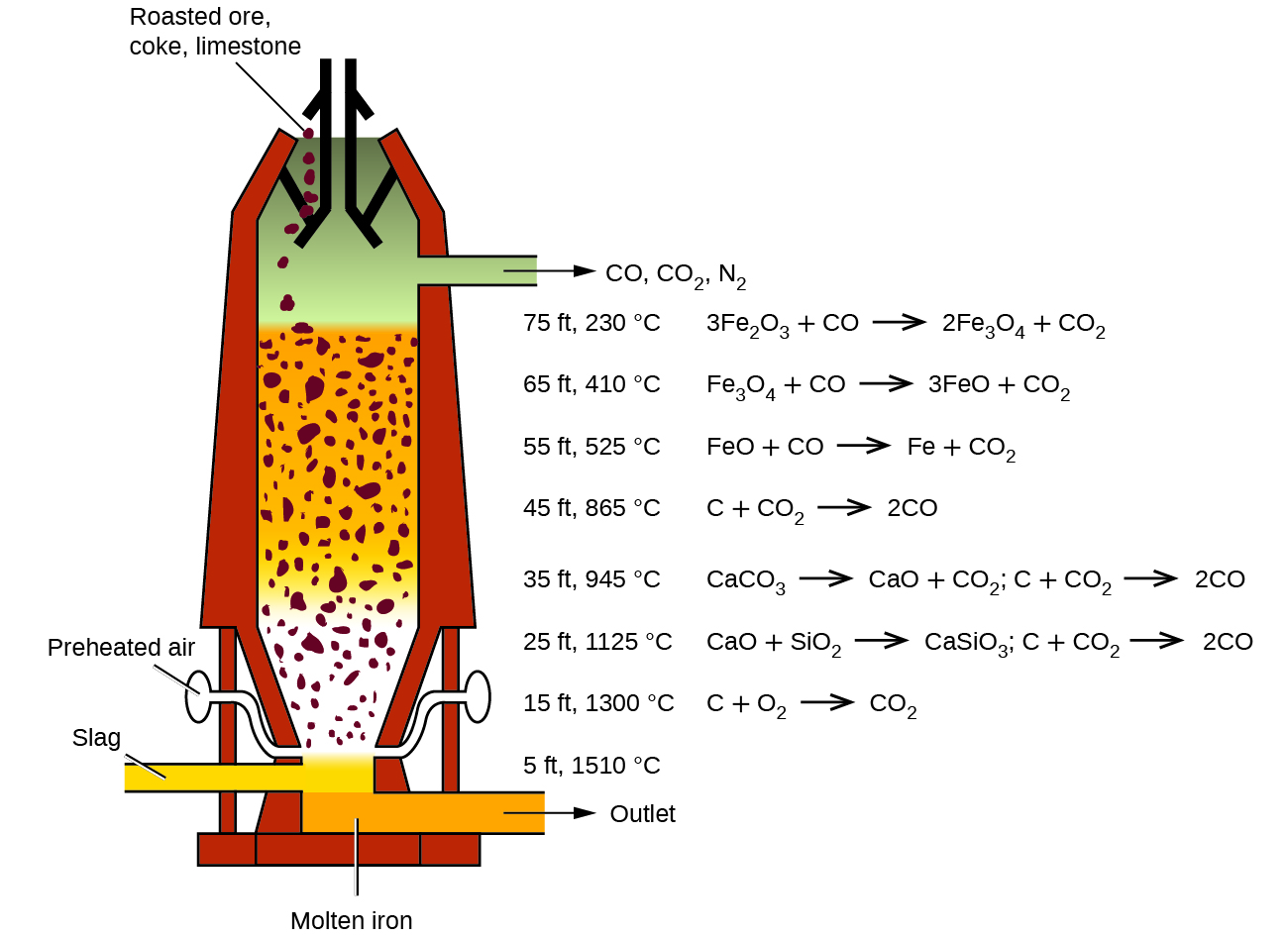

PracticalStudent.com A Blast Furnace is about 100ft. high and produces abut 1000 tons of molten Iron a day. It is made from steel. On the diagram below of the Blast Furnace, just click on the labels for a more detailed description. If you scroll past the diagram you can read about the Blast Furnace Process. Cross-section diagram of a blast furnace - Hagley Digital Archives Elevation section of a mid 20th century blast furnace. Various temperature and chemical reaction zones are shown, with the basic physical components labeled. Likely created between 1930 and 1960. Subject(s) Blast furnaces Metallurgical plants--Equipment and supplies. Find all items with name(s) American Iron and Steel Institute. Draw a neat and labelled diagram of blast furnace. - Toppr Ask 34 mins. Reduction of Metal Oxides to Metals - Applications. 23 mins. Extraction of Fe. 6 mins. Recovery of copper from matte - Bessemer converter for copper. 6 mins.

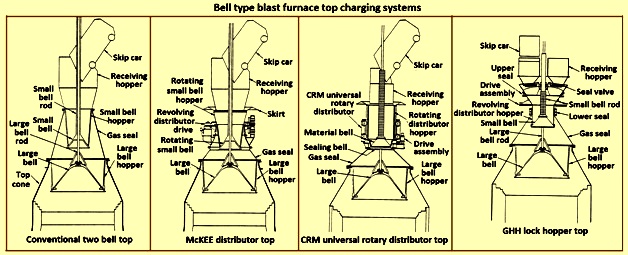

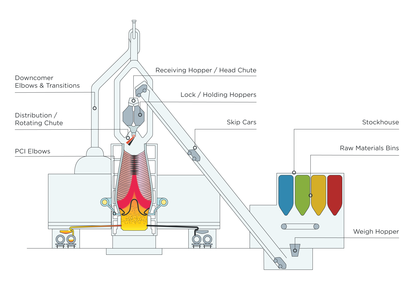

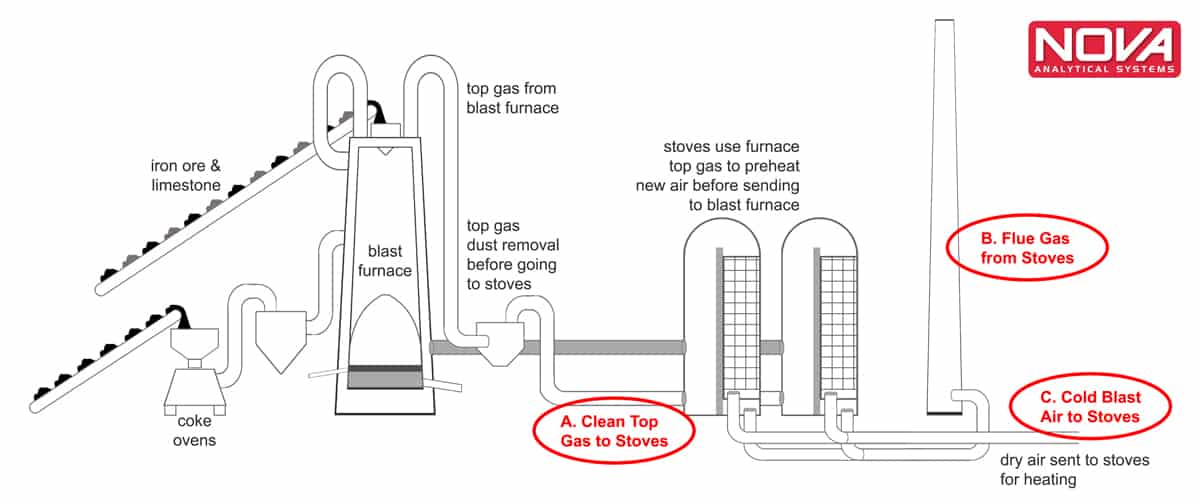

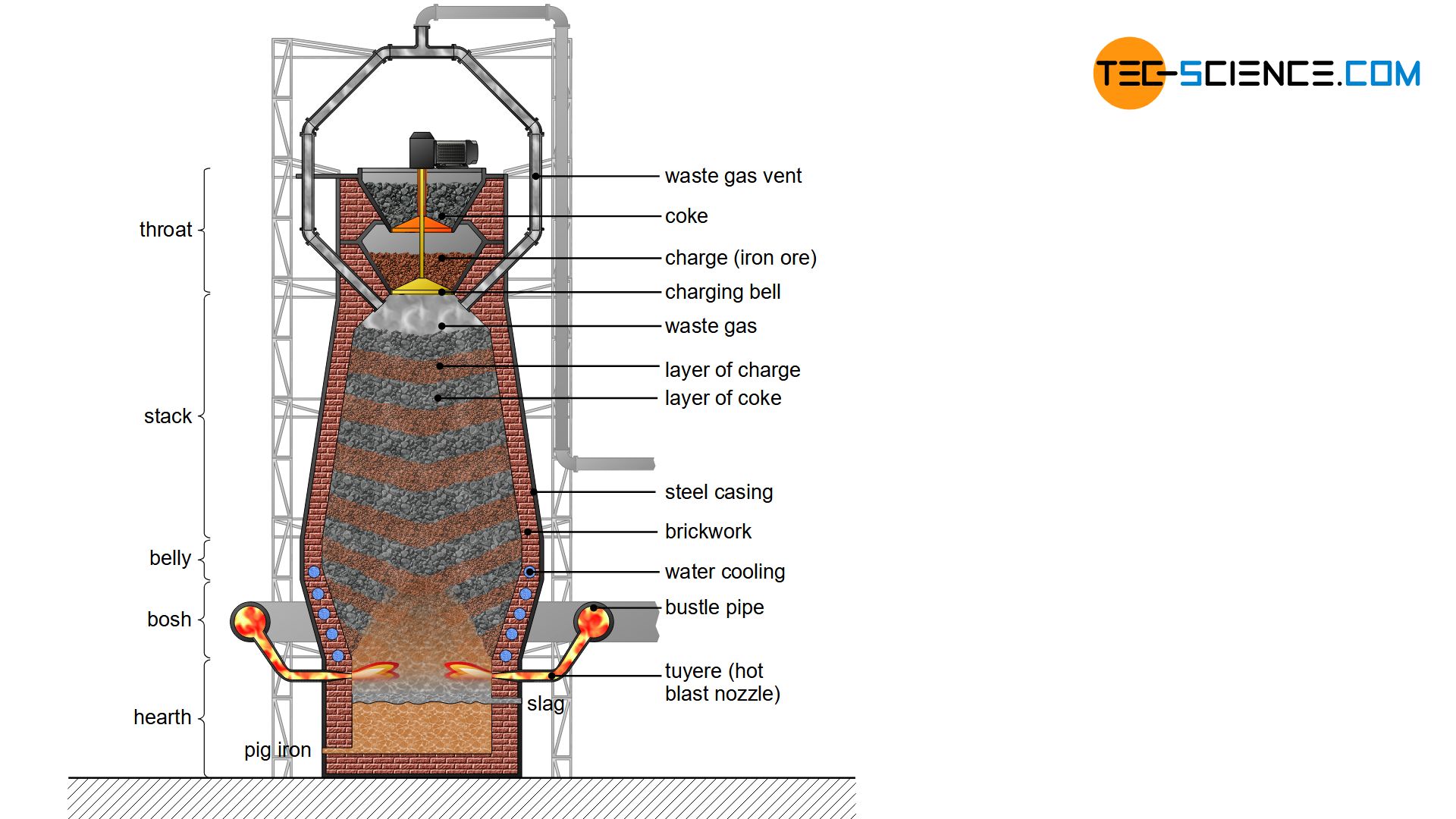

Diagram of blast furnace with labels. Quiz 5.docx - Quiz 5: Metals The blast furnace 1. Complete... View Quiz 5.docx from ENGLISH 1 111 at Sultan Kudarat Polytechnic State College. Quiz 5: Metals The blast furnace 1. Complete the following labels for the diagram of the blast furnace for extracting Blast Furnace - an overview | ScienceDirect Topics Blast furnaces have grown considerably in size during the twentieth century. In the early days of the twentieth century, blast furnaces had a hearth diameter of 4-5 m and were producing around 100,000 THM per year, mostly from lump ore and coke. At the end of the twentieth century the biggest blast furnaces had between 14 and 15 m in hearth diameter, and were producing 3-4 million tons of ... The Blast Furnace - Iron Production A simplified diagram of a Blast Furnace is drawn below. A typical blast furnace may be up to 32 metres in height and 10 metres in diameter. They have thick steel sides, lined with refractory bricks, to ensure that heat is not lost. Blast furnaces are used continuously and are only shut down when their brick lining needs replacing. Blast furnace - Wikipedia A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being "forced" or supplied above atmospheric pressure.. In a blast furnace, fuel (), ores, and flux are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with ...

Solved The blast furnace 1. Complete the following labels - Chegg Complete the following labels for the diagram of the blast furnace for extracting iron. The labels fit in places A-F on the diagram. molten iron out 1500 °C hot gases out blast of hot air in mixture of iron ore, coke and limestone in molten slag out F D 2. Write balanced chemical equations for these reactions which occur in the blast Draw a labelled diagram of blast furance for the extraction of iron? Draw the diagram of a blast furnace used in the extraction of iron and label the following parts : a) Molten iron b) Cone cup arrangement. Medium. View solution > Draw a diagram of the blast furnace used in the extraction of Iron and label the parts. Medium. View solution > Blast Furnace Taphole Clay Materials (Refractories) 27-June-2020. With the prevailing trend of increasing capacities of Blast Furnaces the conditions for applications of Taphole Clay (refractory materials) have become more stringent as there has been a significant increase both in the pig iron temperatures and taping durations. These requirements are met by increasing Al2O3 percent and adding ... PDF The Blast Furnace - Think Bank Education labels themselves. Then ask pupils to come to the SMART Board™ interactive whiteboard and drag the labels to the correct position on the diagram. You can refer back to page 6 to see the completed diagram. Page 8 Activity 3 Page 6 shows a completed diagram of the blast furnace for illustrative purposes. This diagram is also found in

Answered: Complete the following labels for the… | bartleby Complete the following labels for the diagram of the blast furnace for extracting iron. The labels fit in places A-F on the diagram. molten iron out 1500°C hot gases out blast of hot air in mixture of iron ore, coke and limestone in molten slag out Expert Solution Want to see the full answer? Check out a sample Q&A here See Solution star_border Blast Furnace Design, Zones and arrangements for Ironmaking 3600. 2800 (7.7) 100,00000. During this period and till today, Iron & Steel industry and the Refractory industry have been working in tandem with each other to generate a win-win situation and ensure a steady growth for these industries. The equipment and systems of modern Blast Furnace Technology are designed for the harsh environment in the ... Blast Furnace and Process Description - Chemical Engineering World A schematic diagram of a blast furnace is shown in Fig. 1. Blast Furnace and Process Description :- Blast furnace process overview Process Description In the upper part of a hearth about half meter below the edge of the bosh, opening PDF The Blast Furnace Diagram (7K) - creative-chemistry.org.uk The Blast Furnace Diagram (7K) N-m05-22 (© N. Saunders 2000) The Blast Furnace 1. Use the text book to help you to: a) Label the three parts shown by the labelling lines. b) Label the six arrows. c) Add other information that you think is important. 2. Carefully cut out your labelled diagram and stick it into your book. The Blast Furnace 1.

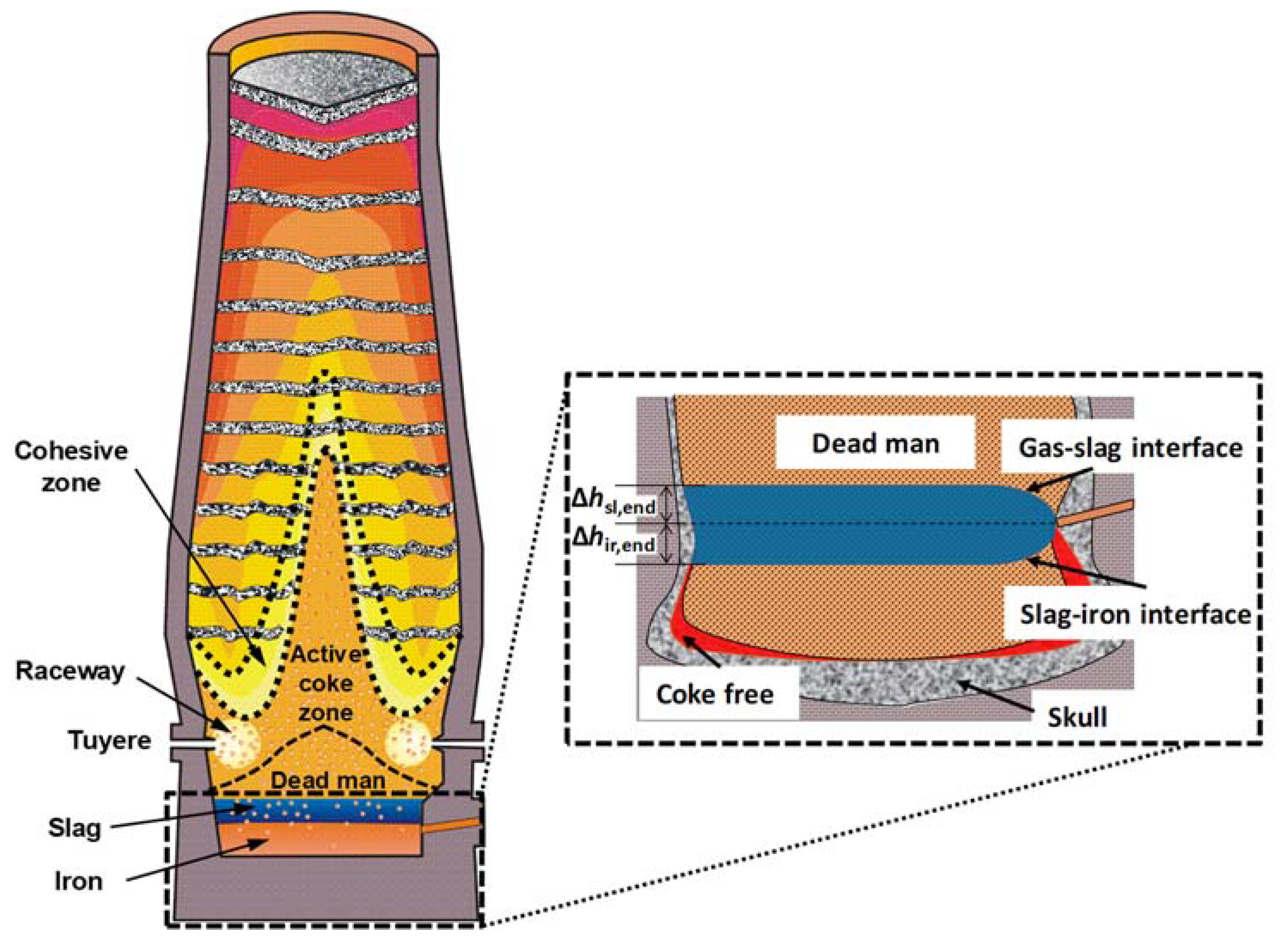

Schematic diagram of the blast furnace process. - ResearchGate Molten iron quality (MIQ) indices prediction based on data-driven models is an important way to monitor product quality and smelting status in the blast furnace ironmaking process. However, some ...

Blast Furnace Process - an overview | ScienceDirect Topics Important properties of sinter for blast furnace process are reducibility, size and size distribution, cold and hot strength, and softening and melting behavior. Typical sinter suitable for blast furnace process is from 15 to 25 mm, as is illustrated in Figure 1.1.10 [22].Another important property is the disintegration of sinter in reduction, which occurs during the transformation of hematite ...

Blast Furnace: Definition, Construction or Parts, Working Principles ... A blast furnace is a large metallic structure that is about 30 meters tall and 10 meters in diameter. It is tapered from the top and bottom with its maximum diameter below its geometric center. The pig iron produced in the process can be used for the production of different forms of steel by mixing impurities Now we will look at construction,

Blast Furnace | Teaching Resources Just a labelled diagram of the blast furnace which can be stuck into their books. Prints equally well in B&W. International; Resources; ... Blast Furnace. Subject: Chemistry. Age range: 14-16. Resource type: Assessment and revision. 5 1 review. ... I found this really useful but I drew in a blank outline of a blast furnace for them to label ...

Historical overview of refractory lining in the blast furnace A blast furnace's refractory liner typically fails owing to any number or combination of these variables. To facilitate comprehension, we will explain the types of refractory lining required in a blast furnace by region, as well as the observed trend in refractory lining patterns over the past few decades. ... "Diagram of Blast Furnace with ...

Outline of blast furnace. (Online version in color.) - ResearchGate The mini blast furnace based on biomass operation is a viable technology that neutralizes fossil carbon emissions in the production route of green hot metal. In this study, we analyze the actual ...

Draw the diagram of blast furnace and label its parts. Draw the diagram of blast furnace and label its parts. cbse; class-10; Share It On Facebook Twitter Email. 1 Answer +1 vote . answered Apr 16, 2020 by KavitaRoy (48.6k points) selected Apr 16, 2020 by Devanshi . Best answer. The diagram of blast furnace used in the extraction of iron is as shown. ...

Blast furnace process - tec-science Blast furnace process By tec-science - 06/21/2018 18070 In the blast furnace, the iron ore reacts with the carbon contained in the coke to form grey or white pig iron. 1 Combustion process 2 Boudouard reaction 3 Preheating 4 Indirect reduction zone 5 Direct reduction zone 6 Carburizing zone 7 Melting zone 8 Tapping zone Combustion process

blast furnace | Definition, Temperature, Diagrams, & Facts Modern blast furnaces range in size from 20 to 110 metres (70 to 360 feet), have hearth diameters of 6 to 15 metres (20 to 50 feet), and can produce from 1,000 to about 15,000 tons of pig iron daily. Steelmaking accounts for about 8 percent of global greenhouse gas emissions—the most of any industry—and these emissions contribute to global warming.

Blast furnace - Teachit A clear simple diagram of the blast furnace for students to label. There is also a PowerPoint version, click to reveal the labels, great for a quick revsion exercise. 54 KB 73.89 KB 209.5 KB Add to favourites

Draw a neat diagram of the blast furnace used in the ... - Vedantu This diagram below represents the temperatures required for each reaction to proceed successfully - Note: We should know that the molten iron from the bottom of the furnace can be used as cast iron. It is very runny when it is molten and doesn't shrink much when it solidifies. It is therefore ideal for making castings as the name suggests.

Draw a neat and labelled diagram of blast furnace. - Toppr Ask 34 mins. Reduction of Metal Oxides to Metals - Applications. 23 mins. Extraction of Fe. 6 mins. Recovery of copper from matte - Bessemer converter for copper. 6 mins.

Cross-section diagram of a blast furnace - Hagley Digital Archives Elevation section of a mid 20th century blast furnace. Various temperature and chemical reaction zones are shown, with the basic physical components labeled. Likely created between 1930 and 1960. Subject(s) Blast furnaces Metallurgical plants--Equipment and supplies. Find all items with name(s) American Iron and Steel Institute.

PracticalStudent.com A Blast Furnace is about 100ft. high and produces abut 1000 tons of molten Iron a day. It is made from steel. On the diagram below of the Blast Furnace, just click on the labels for a more detailed description. If you scroll past the diagram you can read about the Blast Furnace Process.

Post a Comment for "43 diagram of blast furnace with labels"